Lift

Tool to operate forklift remotely

Second Prize

Envision the Future of the Lift Truck

Toyota and Autodesk design contest - 2022

Problem

How might we engage fork lift operators in their jobs to encourage employment and prevent injury or operation errors ?

Introducing Lift

Control technology experience for forklift operators to conduct their job remotely through a customised simulation that increases passion and reduces risk on the job.

Area of interest

Workforce

What forklift enhancements in universal design would benefit novice, expert, GenZ and aging operators?

Space

How would a forklift on the moon be different than one on earth?

Work environment

What improvements will aid in work environments with robots and pedestrians as well as manual, remote and automated forklifts?

Human Machine Interface

How can controls and the flow of information be improved?

Electrification

What are the owner and operator perceptions about electric forklifts outdoors?

Mobile Workstation

What amenities, improved comfort and storage enhancements are possible?

Research

7,000

lift truck drivers left the UK logistics industry in 2019

75 to 100

workers are killed annually in forklift accidents

34,900

serious injuries annually.

Lack of Safety

Shortage of Operators

Source

Occupational Health and Safety Administration: https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=FEDERAL_REGISTER&p_id=13456

Welfaux Materials Handling: https://www.welfauxmh.co.uk/why-the-uk-forklift-operator-crisis-is-accelerating-sales-of-automated-handling-solutions

Remote Operation is the future

Why?

Globallly hire operator

Physical disabilities

Reduces operators risk

Control multiple forklift

Reduces commuting stress

Product planning

Current state (now)

Operators drive on-site

Why this product

Remote operation reduces job risk and can improve engagement

Potential Problems

Technical Challenges

Building/maintaining trust.

Mental illness

Working from different locations, time zones, etc

Nerve issues

Learning and adapting to the tool

Lack of users dedication

Lack of precision

Potential Solutions

Gamifying the job experience with a simulated environment.

Specialised controls and new methods of driving.

Sturdy

Dedicated feel to the work and work flow to reduce the risk

Excitement

Game aspect of the working scenario to engage the user.

Inspiration from trip to Toyota Material Handling Northern California

Camouflage

The dark grey camouflage with the warehouse environment.

Color Break and Accent

The orange accent is makes the forklift appearance less chunky

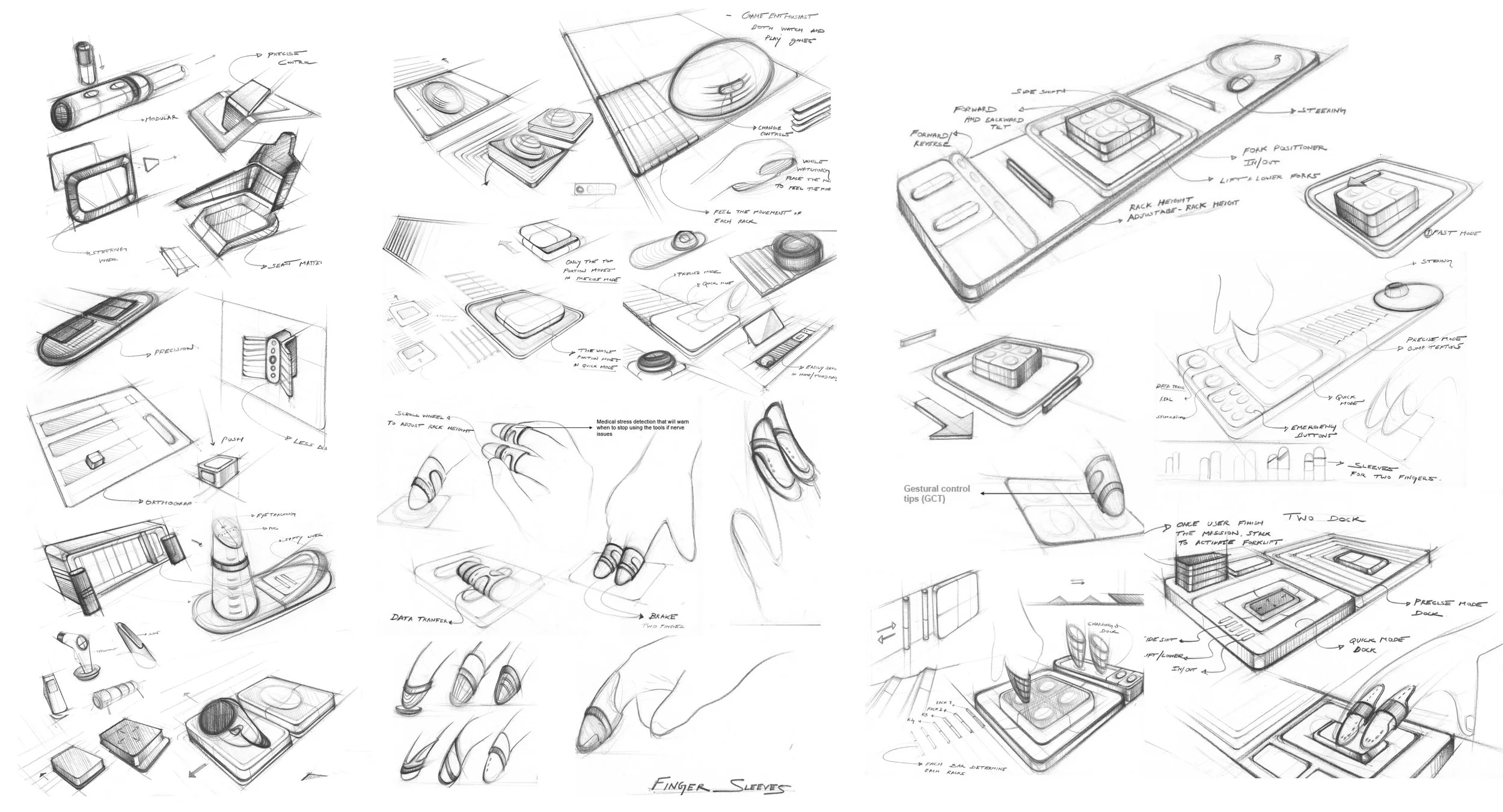

Concept Development

How it works?

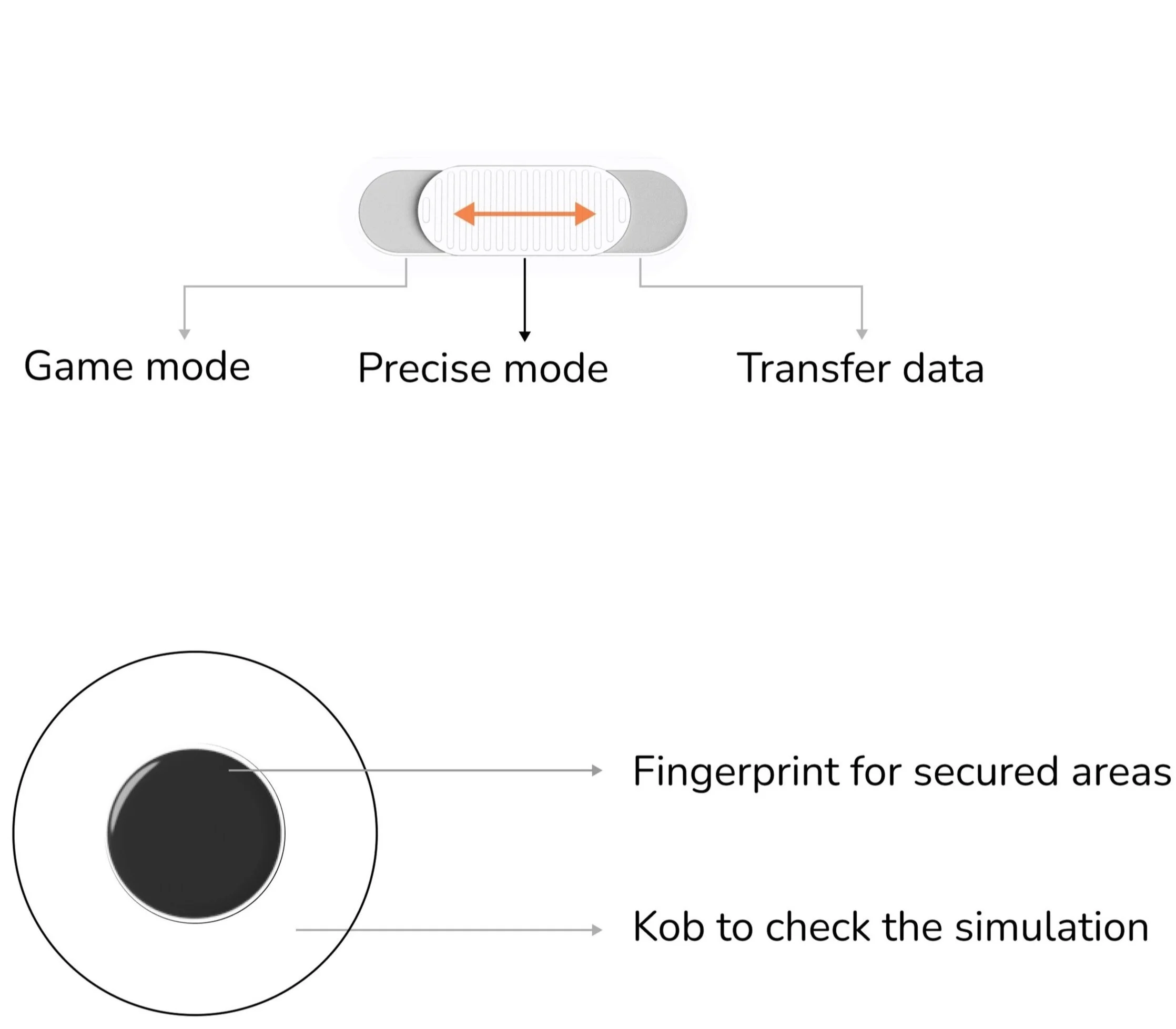

SIMULATED GAME MODE

TO DRIVE AND OPERATE

Choose the look of the simplified warehouse they are navigating through.

Precision points to engage operators.

Work faster than they would on-site.

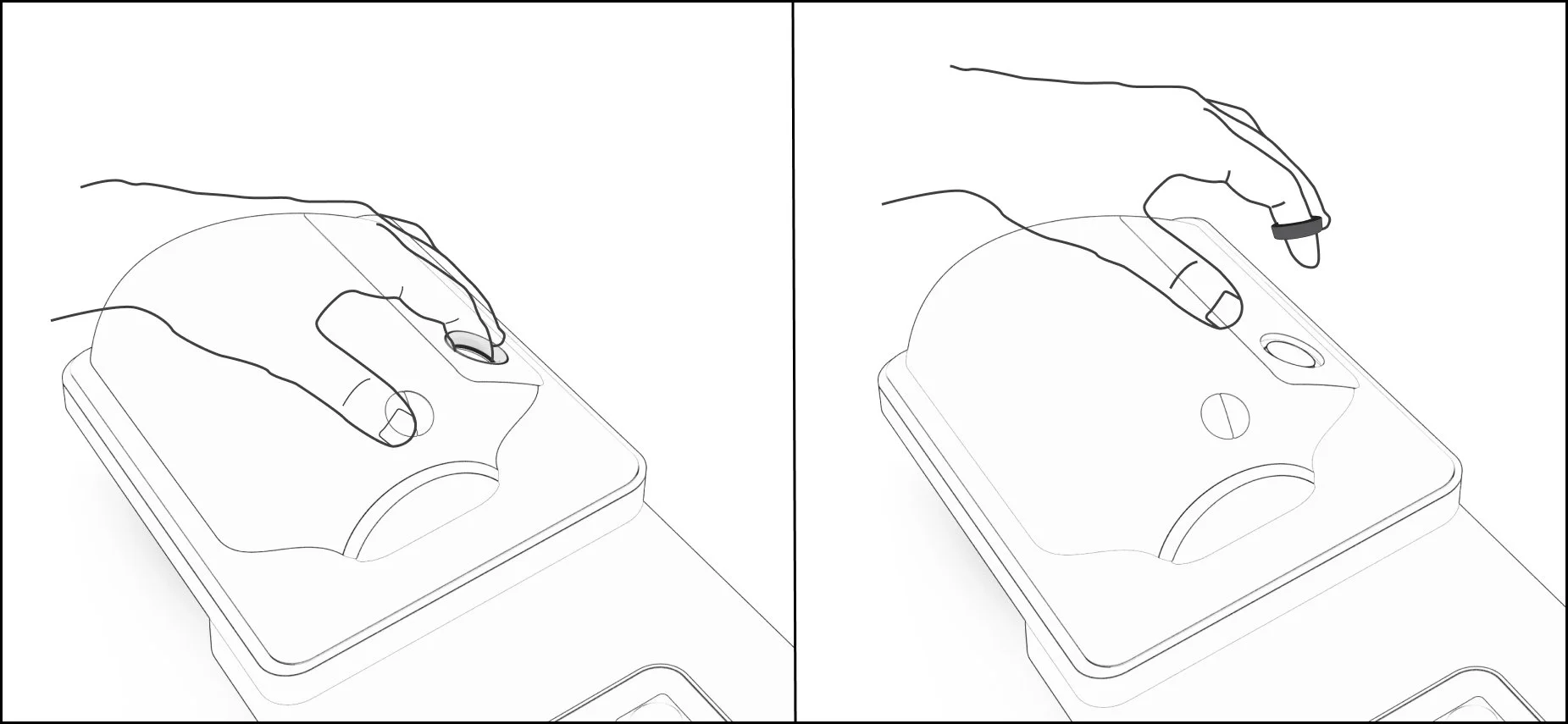

Gesture Control Ring operate the robotic vehicle

SIMULATED PRECISE MODE

TO CHECK FOR ERRORS

Enter into a real environment simulation.

Check for errors or potential problems before transferring data into reality.

TRASFER DATA

SEND THE SIMULATED DATA TO REALITY

Portability

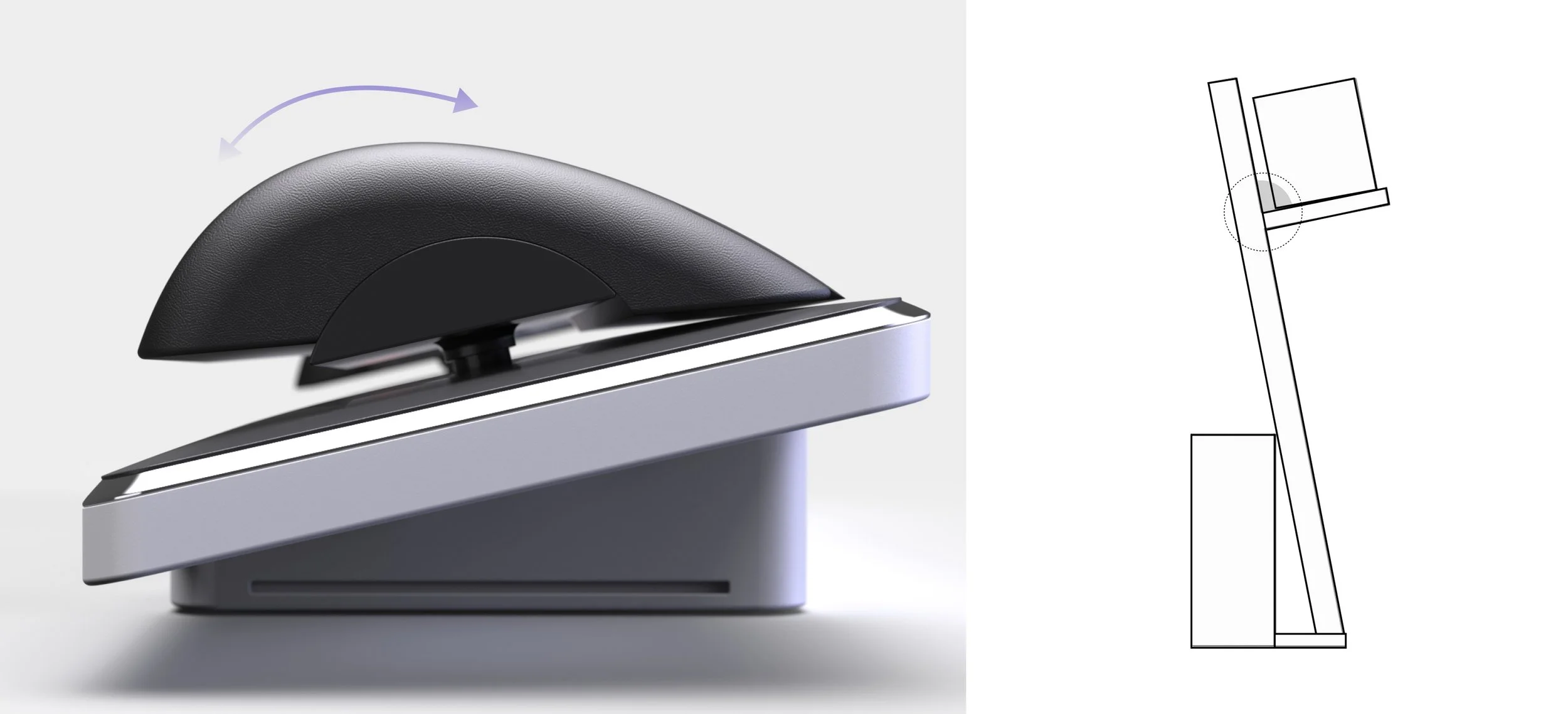

The slidable design allows users to take their controllers with them and operate in any location including co-working spaces or even coffee shops.

Driving

Slight movements and rotations control the lift and allow for optimal comfort for the operator

Fork operations

Use the key to lift and lower forks

Rotate slightly to tilt forks

Slide left and right to side shift forks

Push front and back to in/out forks

Gesture Control Ring (GCR)

The GCR is an accessory that allows operators to program specific controls for driving other robotic vehicles like drones.

Push and hold 3 sec to take out GCR

Key set

Key set can be swapped based on controls needed for specific vehicles beyond forklifts.

Before transferring data, the operator will need to confirm using their fingerprint to avoid accidental or unauthorised transfers.